Transform your home’s comfort, energy efficiency, and value with a well-planned window replacement project that eliminates common pitfalls and surprises.

At Lux Square Construction, we understand that planning a window replacement project can feel overwhelming for Massachusetts homeowners, especially when you’re balancing quality expectations, budget constraints, and the desire to minimize disruption to your daily life. Whether you’re dealing with drafty windows in your Stoughton colonial, outdated single-pane windows in your Norwood ranch, or simply want to upgrade to more energy-efficient options throughout the South Shore region, a well-planned approach makes the difference between a stressful ordeal and a smooth transformation that enhances your home’s comfort and value. Our experience serving homeowners throughout Massachusetts has taught us that successful window replacement projects share common characteristics: thorough planning, realistic timelines, clear communication, and attention to details that many homeowners overlook until it’s too late. The key to a stress-free window replacement lies not just in selecting quality windows and experienced installers, but in understanding the entire process from initial assessment through final cleanup, anticipating potential challenges, and making informed decisions that align with your home’s specific needs and your family’s lifestyle. By following a systematic approach to planning, you can avoid the common pitfalls that turn window replacement from an exciting home improvement into a source of frustration and unexpected expenses.

The complexity of window replacement projects in Massachusetts is amplified by the state’s diverse housing stock, ranging from historic colonials built in the 1700s to modern contemporary homes, each presenting unique challenges and opportunities. Add to this the region’s demanding climate conditions, strict energy codes, and the need to maintain architectural integrity, and it becomes clear why proper planning is essential for project success. Our comprehensive guide will walk you through every aspect of window replacement planning, from initial assessment and budgeting through contractor selection and project management, ensuring your investment delivers maximum value and satisfaction.

Understanding Your Window Replacement Needs and Goals

Before diving into product selection or contractor interviews, successful window replacement projects begin with a thorough assessment of your current windows and a clear understanding of what you hope to achieve through replacement. This foundational step prevents costly mistakes and ensures that your new windows address your specific concerns while aligning with your long-term goals for comfort, energy efficiency, and home value.

The assessment process should begin with a comprehensive evaluation of your existing windows’ condition, performance, and remaining useful life. Many Massachusetts homeowners are surprised to discover that not all windows in their home require immediate replacement, and a strategic approach that prioritizes the most problematic windows can spread costs over multiple years while addressing urgent needs first. Look for obvious signs of window failure including visible rot or decay in wooden frames, broken or cracked glass, windows that won’t open or close properly, and noticeable air leaks around frames or sashes.

Energy performance evaluation requires more subtle observation but can reveal significant opportunities for improvement. During winter months, feel for cold drafts around window frames, check for condensation between double-pane glass layers, and notice whether certain rooms are consistently harder to heat or cool than others. These symptoms often indicate seal failures, inadequate insulation, or single-pane windows that are dramatically underperforming compared to modern standards. The Massachusetts climate’s extreme temperature variations make energy-efficient windows particularly valuable, with potential energy savings that can offset replacement costs over time.

Functional issues extend beyond energy performance to include operational problems that affect daily life and home security. Windows that are difficult to open create safety concerns in emergency situations, while those that won’t stay open or closed properly can be frustrating and may indicate hardware failure or frame warping. Security considerations become important for ground-floor windows or those in secluded areas, where modern locking mechanisms and impact-resistant glass can provide peace of mind along with improved performance.

Aesthetic goals often drive window replacement decisions, particularly in homes where outdated window styles detract from architectural character or curb appeal. However, aesthetic improvements should be balanced with performance requirements and budget constraints to ensure that your investment delivers both visual appeal and functional benefits. Consider how new windows will complement your home’s architectural style, whether you want to maintain historical accuracy or update to a more contemporary look, and how window selection might affect other planned improvements like siding or exterior painting.

Budget planning requires honest assessment of both immediate costs and long-term value considerations. Window replacement represents a significant investment that can range from $300 to $1,500 per window depending on size, style, and performance features, with total project costs often reaching $10,000 to $30,000 or more for whole-house replacement. However, these costs must be weighed against potential energy savings, increased home value, improved comfort, and reduced maintenance requirements that quality windows provide over their 20-30 year lifespan.

Timeline considerations affect both project planning and daily life disruption. Window replacement projects can typically be completed in one to three days for most homes, but scheduling, permitting, and manufacturing lead times can extend the overall timeline to several weeks or months. Understanding these timeframes helps you plan around family schedules, weather considerations, and other home improvement projects that might be coordinated with window replacement.

1. Choosing the Right Window Types and Features for Massachusetts Homes

Selecting appropriate window types and performance features requires understanding how different options perform in Massachusetts’ challenging climate while meeting your specific functional and aesthetic requirements. The state’s extreme temperature variations, high humidity levels, and coastal salt exposure in some areas create demanding conditions that separate high-quality windows from inferior products over time.

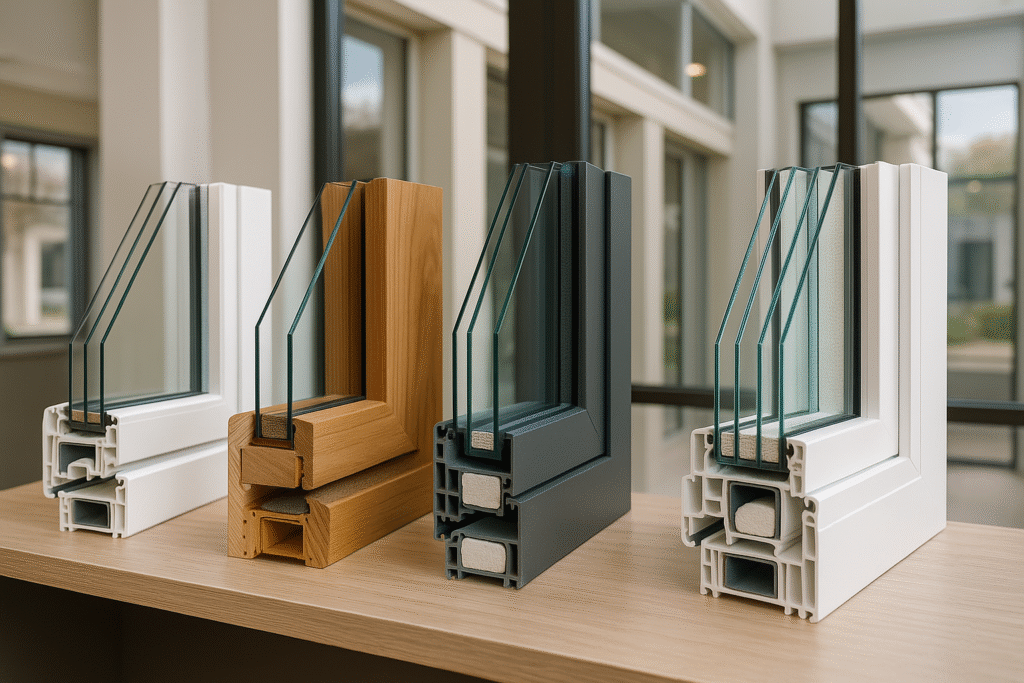

Frame material selection significantly impacts both performance and maintenance requirements, with each option offering distinct advantages and considerations for Massachusetts homeowners. Vinyl frames have become increasingly popular due to their excellent insulation properties, low maintenance requirements, and resistance to moisture damage that can plague wood frames in humid coastal areas. Modern vinyl frames feature multi-chamber construction that enhances insulation performance while providing structural strength, and quality vinyl windows can last 20-30 years with minimal maintenance beyond occasional cleaning.

Wood frames offer superior aesthetic appeal and can be essential for maintaining historical accuracy in older homes, but they require more maintenance and careful attention to moisture protection in Massachusetts’ climate. However, modern wood windows often feature aluminum or vinyl cladding on the exterior that provides weather protection while maintaining wood’s natural beauty on the interior. These clad wood windows combine aesthetic appeal with improved durability, though they typically command premium prices compared to vinyl or aluminum options.

Fiberglass frames represent a premium option that combines the aesthetic appeal of wood with superior durability and dimensional stability. Fiberglass windows resist expansion and contraction better than vinyl, maintain their appearance longer than wood, and can be painted to match any color scheme. While more expensive than vinyl options, fiberglass windows often provide the best long-term value for homeowners who prioritize durability and low maintenance.

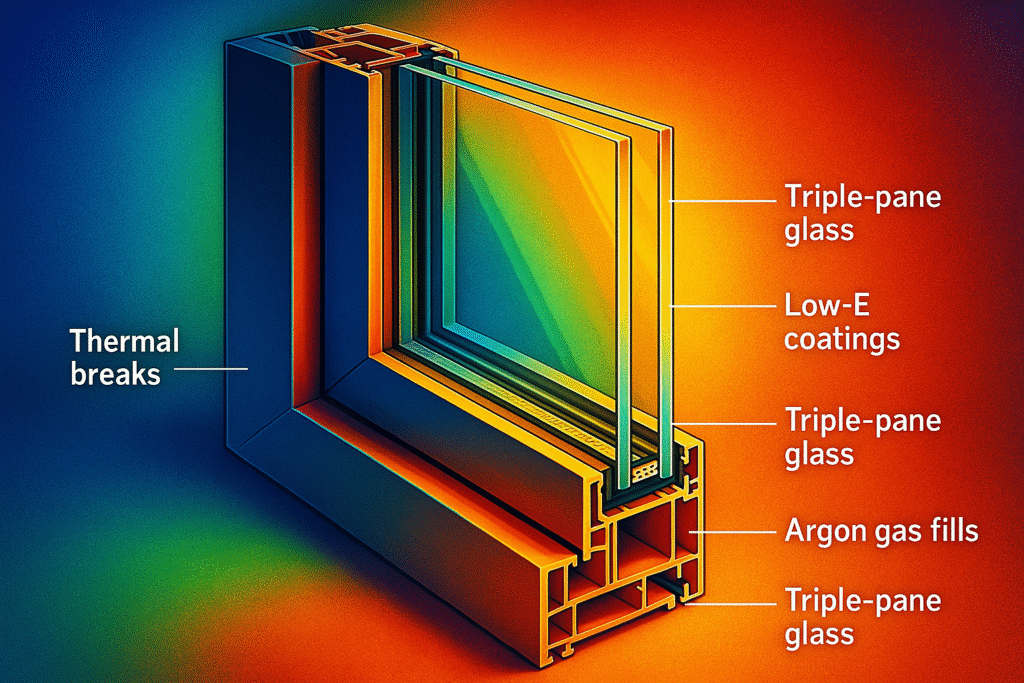

Glass package selection has perhaps the greatest impact on energy performance and comfort, with modern options providing dramatic improvements over single-pane windows common in older Massachusetts homes. Double-pane windows with low-E coatings and argon gas fills represent the minimum standard for energy efficiency, providing significant improvements in insulation performance while reducing condensation and improving comfort near windows.

Triple-pane windows offer even greater energy efficiency and are becoming increasingly popular in Massachusetts as energy codes become more stringent and homeowners seek maximum comfort and energy savings. While more expensive than double-pane options, triple-pane windows can provide noticeable improvements in comfort and energy performance, particularly in rooms with large window areas or challenging exposures.

Low-E coatings and gas fills between glass panes significantly enhance energy performance by reflecting heat back into rooms during winter while blocking solar heat gain during summer. Different low-E coating formulations are optimized for different climate zones, and selecting the appropriate coating for Massachusetts’ mixed climate ensures optimal year-round performance.

Window style selection affects both aesthetics and functionality, with each style offering specific advantages for different applications and architectural contexts. Double-hung windows remain the most popular choice for traditional Massachusetts homes, providing classic aesthetics with modern performance features like tilt-in sashes for easy cleaning and improved hardware for smooth operation.

Casement windows offer superior energy performance due to their compression sealing when closed, making them excellent choices for areas where energy efficiency is paramount. The side-hinged operation provides excellent ventilation control and unobstructed views, though they may not be appropriate for all architectural styles or locations where exterior clearance is limited.

Sliding windows work well for contemporary homes or areas where exterior clearance prevents casement operation, though they typically don’t seal as tightly as casement or double-hung options. Picture windows and other fixed styles provide maximum glass area and energy efficiency for areas where ventilation isn’t required, often serving as focal points in living areas or providing dramatic views.

Specialty shapes and custom sizes can address unique architectural features or design goals, though they typically command premium prices and longer lead times. Bay and bow windows create additional interior space while providing enhanced natural light and views, making them popular choices for kitchen and living areas despite their higher costs and more complex installation requirements.

2. Budgeting and Financing Your Window Replacement Project

Developing a realistic budget for window replacement requires understanding the various cost components and financing options available to Massachusetts homeowners, while planning for potential unexpected expenses that can arise during installation. A well-structured budget prevents financial stress and ensures that your project can be completed without compromising quality or leaving you with incomplete work.

Material costs typically represent 40-60% of total project expenses, varying significantly based on window type, size, and performance features. Basic vinyl double-hung windows might cost $300-$600 per window, while premium fiberglass or wood-clad options can range from $800-$1,500 or more per window. Specialty shapes, custom sizes, and high-performance features like triple-pane glass or advanced low-E coatings add to material costs but may provide long-term value through energy savings and enhanced comfort.

Installation costs generally range from $200-$500 per window for standard installations, though complex situations involving structural modifications, trim work, or challenging access can increase labor costs significantly. The condition of existing window openings, need for additional insulation or air sealing, and coordination with other trades can all affect installation complexity and costs. Experienced contractors like Lux Square Construction provide detailed estimates that account for these variables, helping prevent budget surprises during installation.

Permit and inspection fees vary by municipality but typically range from $50-$200 for residential window replacement projects. Some Massachusetts communities require permits for window replacement, particularly when changing window sizes or types, while others may exempt simple replacement projects. Understanding local requirements early in the planning process prevents delays and ensures compliance with building codes.

Additional costs often overlooked in initial budgeting include window treatments for new windows, potential exterior trim or siding repairs revealed during installation, and temporary heating or cooling costs if installation occurs during extreme weather. Interior trim work may be required if new windows have different dimensions than existing ones, and exterior caulking or touch-up painting is often needed to complete the installation properly.

Financing options can make window replacement more accessible while allowing homeowners to choose higher-quality windows that provide better long-term value. Many window manufacturers and contractors offer financing programs with competitive interest rates and flexible terms, allowing you to spread costs over several years while enjoying immediate benefits of improved comfort and energy efficiency.

Home equity loans or lines of credit often provide the lowest interest rates for window replacement projects, particularly for homeowners with significant equity and good credit. These options allow you to borrow against your home’s value at rates typically lower than personal loans or credit cards, though they do put your home at risk if you’re unable to make payments.

Energy efficiency rebates and tax credits can offset window replacement costs while encouraging upgrades to high-performance windows. Massachusetts utilities often offer rebates for ENERGY STAR qualified windows, and federal tax credits may be available for windows meeting specific energy performance criteria. These incentives change periodically, so research current programs before finalizing your window selection.

Cash payment often provides the best overall value by avoiding interest charges and may qualify for contractor discounts. If you have sufficient savings, paying cash eliminates financing costs and simplifies the transaction, though you should maintain adequate emergency reserves for unexpected expenses.

Budget contingency planning should include 10-20% additional funds for unexpected issues that commonly arise during window replacement projects. Structural problems, additional insulation needs, or exterior repairs discovered during installation can add to project costs, and having contingency funds available prevents project delays or quality compromises.

Value engineering involves balancing performance features with budget constraints to maximize your investment’s return. This might mean choosing double-pane windows with quality low-E coatings instead of triple-pane options, or selecting vinyl frames instead of wood-clad alternatives while maintaining energy performance standards that provide meaningful benefits.

3. Selecting and Vetting Window Replacement Contractors

Choosing the right contractor is perhaps the most critical decision in your window replacement project, as even the highest-quality windows can fail to perform properly if installed incorrectly. Massachusetts homeowners have access to numerous window replacement contractors, but finding one with the experience, credentials, and commitment to quality that ensures project success requires careful research and evaluation.

Licensing and insurance verification should be your first step in contractor evaluation, as these credentials protect you from liability and ensure that contractors meet minimum professional standards. Massachusetts requires contractors performing work over $1,000 to hold a Home Improvement Contractor license, and you can verify licensing status through the state’s consumer affairs website. General liability insurance protects you from property damage during installation, while workers’ compensation coverage protects you from liability if workers are injured on your property.

Experience and specialization in window replacement distinguish contractors who understand the nuances of proper installation from general handymen who may lack specific expertise. Look for contractors who specialize in window replacement rather than those who offer it as one of many services, as specialized contractors typically have better relationships with manufacturers, more experience with installation challenges, and greater knowledge of local building codes and energy requirements.

References and portfolio review provide insight into contractor quality and customer satisfaction that goes beyond marketing materials. Request references from recent projects similar to yours, and don’t hesitate to contact previous customers about their experience with the contractor’s work quality, timeliness, communication, and problem resolution. A quality contractor should be proud to share their work and customer feedback.

Manufacturer certifications indicate that contractors have received specific training on proper installation techniques for the window brands they install. Many major window manufacturers offer certification programs that ensure contractors understand their products’ installation requirements and warranty conditions. Certified installers often provide better warranty coverage and are more likely to install windows correctly the first time.

Local reputation and Better Business Bureau ratings provide additional insight into contractor reliability and customer service. Check online reviews on multiple platforms, but remember that a few negative reviews among many positive ones may not be concerning, while patterns of similar complaints should raise red flags. Local building supply stores and other contractors can also provide informal references about contractors’ reputations in the professional community.

Estimate comparison requires more than simply choosing the lowest price, as significant price differences often reflect variations in window quality, installation practices, or included services. Quality contractors provide detailed estimates that specify window models, installation procedures, cleanup services, and warranty terms, allowing meaningful comparison between proposals. Be wary of estimates that are significantly lower than others, as they may indicate inferior products, shortcuts in installation, or hidden costs that emerge later.

Communication and professionalism during the estimate process often predict how contractors will handle your project. Quality contractors arrive on time for appointments, provide detailed explanations of their recommendations, answer questions thoroughly, and follow up promptly with written estimates. Poor communication during the sales process typically continues during installation, leading to frustration and potential problems.

Contract terms and warranty coverage protect your investment and ensure that any problems are addressed promptly and fairly. Quality contractors provide written contracts that specify window models, installation procedures, timeline, payment schedule, and warranty terms. Manufacturer warranties typically cover window defects, while contractor warranties should cover installation workmanship for at least one year.

Payment schedules should never require full payment upfront, as this eliminates your leverage if problems arise during installation. Reasonable payment schedules might include a small deposit to order windows, partial payment upon delivery, and final payment upon completion and your satisfaction with the work. Be wary of contractors who demand large upfront payments or cash-only transactions.

4. Project Timeline and Scheduling Considerations

Understanding the window replacement timeline helps you plan around family schedules, weather considerations, and other home improvement projects while setting realistic expectations for project completion. Massachusetts’ seasonal weather patterns, contractor availability, and manufacturing lead times all affect project scheduling and require careful coordination for optimal results.

Pre-installation timeline typically spans 4-8 weeks from contract signing to installation start, though this can vary significantly based on window availability, contractor schedules, and permit requirements. Custom windows or specialty sizes may require 6-12 weeks for manufacturing, while standard sizes from major manufacturers might be available in 2-4 weeks. Planning ahead allows you to schedule installation during optimal weather conditions and avoid peak demand periods when contractors may be less available.

Permit acquisition can add 1-3 weeks to the timeline depending on local requirements and municipal processing times. Some Massachusetts communities require permits for window replacement, particularly when changing window sizes or types, while others may exempt simple replacement projects. Submit permit applications early in the process to avoid delays, and ensure that your contractor is familiar with local requirements and can handle permit submission if needed.

Weather considerations are particularly important in Massachusetts, where winter conditions can complicate installation and extreme summer heat can be uncomfortable for both workers and homeowners. Spring and fall typically provide optimal installation conditions with moderate temperatures and lower precipitation, though these seasons also represent peak demand periods when contractors may be busiest and scheduling may be more challenging.

Installation duration varies based on project scope, window types, and installation complexity, but most residential projects can be completed in 1-3 days. Simple replacement of standard-sized windows in good openings might take just one day, while complex projects involving structural modifications, custom sizes, or challenging access can require several days. Discuss timeline expectations with your contractor and plan for potential delays due to weather or unexpected complications.

Preparation requirements help ensure smooth installation and minimize disruption to your daily routine. Remove window treatments, furniture, and decorations from areas around windows before installation begins. Protect valuable items from dust and debris, and plan alternative arrangements if installation affects rooms you use regularly. Clear exterior access to windows and ensure that contractors have adequate parking and storage space for materials and equipment.

Daily schedule coordination helps minimize disruption while ensuring that you’re available to address questions or concerns that arise during installation. Most contractors prefer to start early in the morning to maximize daylight hours, and installation typically involves significant noise and activity that may affect work-from-home schedules or young children’s routines. Discuss daily schedules with your contractor and plan accordingly.

Quality control checkpoints throughout the installation process help ensure that work meets your expectations and any issues are addressed promptly. Inspect each window as installation progresses, checking for proper operation, adequate sealing, and aesthetic appearance. Address any concerns immediately rather than waiting until project completion, as corrections are typically easier to make during installation.

Final inspection and cleanup should be completed before making final payment, ensuring that all work meets contract specifications and your satisfaction. Test all windows for proper operation, check for adequate caulking and weatherproofing, and verify that cleanup has been completed to your standards. Quality contractors take pride in leaving job sites clean and addressing any final concerns before considering the project complete.

5. Maximizing Energy Efficiency and Long-Term Performance

Achieving maximum energy efficiency and long-term performance from your window replacement investment requires attention to details beyond window selection, including proper installation practices, complementary improvements, and ongoing maintenance that preserves performance over time. Massachusetts’ demanding climate conditions make these considerations particularly important for realizing the full benefits of your investment.

Air sealing and insulation improvements often provide the greatest energy performance gains when combined with window replacement, as even high-performance windows can underperform if installed in poorly sealed openings. Proper installation includes removing old caulking and weatherstripping, sealing gaps between window frames and rough openings with appropriate materials, and ensuring that insulation completely fills voids around windows without compression that reduces effectiveness.

Thermal bridging reduction involves addressing heat transfer paths through window frames and surrounding structure that can compromise energy performance even with quality windows. Continuous insulation around window openings, thermal breaks in metal frames, and proper flashing details all contribute to minimizing thermal bridging and maximizing energy efficiency.

Moisture management prevents condensation problems that can damage windows and surrounding structure while creating uncomfortable indoor conditions. Proper vapor barriers, adequate ventilation, and humidity control help prevent condensation on windows and ensure long-term performance. Understanding how different window types and glass packages perform in various humidity conditions helps optimize comfort and prevent problems.

Window orientation and shading considerations affect both energy performance and comfort, with south-facing windows providing beneficial solar heat gain during winter while potentially causing overheating during summer. Proper window selection for different orientations, combined with appropriate shading strategies, optimizes year-round performance and comfort.

Maintenance requirements vary by window type and frame material, but all windows benefit from regular cleaning, lubrication of moving parts, and inspection of weatherstripping and caulking. Establishing a maintenance routine preserves window performance and appearance while identifying potential problems before they become serious issues requiring expensive repairs.

Performance monitoring helps you understand how your new windows are performing and identify opportunities for additional improvements. Notice changes in comfort levels, energy bills, and indoor air quality that indicate how well your windows are performing. Document any issues that arise and address them promptly to maintain optimal performance.

Complementary improvements like storm doors, window treatments, and landscaping can enhance window performance while providing additional benefits. Energy-efficient window treatments can provide additional insulation during extreme weather, while strategic landscaping can provide summer shading and winter wind protection that enhances overall energy performance.

Ready to transform your home with a stress-free window replacement project that enhances comfort, energy efficiency, and value? Contact Lux Square Construction today for a comprehensive consultation and detailed project plan tailored to your specific needs and goals. Our experienced team will guide you through every step of the process, from initial assessment and product selection through professional installation and final inspection, ensuring that your investment delivers maximum performance and satisfaction for decades to come. Don’t let another season pass with inefficient, uncomfortable windows – call us at (781) 408-5000 or visit our Stoughton showroom to discover how proper planning and expert installation can make your window replacement project a smooth, successful experience that exceeds your expectations.

Frequently Asked Questions

How long do window replacement projects typically take in Massachusetts? Most residential window replacement projects can be completed in 1-3 days, depending on the number of windows and installation complexity. However, the total timeline from contract signing to completion typically spans 6-10 weeks, including manufacturing lead times, permit acquisition, and scheduling. Custom windows or specialty sizes may require longer manufacturing times, while standard sizes from major manufacturers are typically available in 4-6 weeks.

What’s the best time of year to replace windows in Massachusetts? Spring and fall typically provide optimal installation conditions with moderate temperatures and lower precipitation, though these seasons also represent peak demand periods. Summer installation is possible but can be uncomfortable during heat waves, while winter installation requires special precautions but may offer better contractor availability and pricing. Plan your project timing based on your priorities for weather conditions, contractor availability, and pricing.

Do I need permits for window replacement in Massachusetts? Permit requirements vary by municipality, with some communities requiring permits for all window replacement while others exempt simple replacement projects. Permits are typically required when changing window sizes, types, or structural openings. Check with your local building department early in the planning process, and ensure that your contractor is familiar with local requirements and can handle permit submission if needed.

How much can I expect to save on energy bills with new windows? Energy savings vary significantly based on your existing windows, new window performance, home size, and energy usage patterns. Replacing single-pane windows with quality double-pane units can reduce heating and cooling costs by 15-25%, while upgrading from older double-pane windows might provide 5-15% savings. Triple-pane windows and advanced low-E coatings can provide additional savings, particularly in homes with large window areas or challenging exposures.

Should I replace all windows at once or do it in phases? Both approaches have advantages depending on your budget, priorities, and home conditions. Whole-house replacement often provides better pricing per window and ensures consistent appearance and performance, while phased replacement allows you to spread costs over time and prioritize the most problematic windows first. Consider your budget constraints, energy priorities, and aesthetic goals when deciding on project scope.

What should I do if problems arise during installation? Address any concerns immediately with your contractor rather than waiting until project completion, as corrections are typically easier to make during installation. Document any issues with photos and written descriptions, and ensure that problems are resolved to your satisfaction before making final payment. Quality contractors stand behind their work and should address legitimate concerns promptly and professionally.

How do I maintain my new windows for optimal performance? Regular maintenance includes cleaning glass and frames, lubricating moving parts annually, inspecting and replacing weatherstripping as needed, and checking caulking around frames for gaps or deterioration. Most window manufacturers provide specific maintenance guidelines for their products, and following these recommendations helps preserve warranty coverage while ensuring optimal performance and longevity.